Case Studies

An additional benefit was a nearly 100% increase in part production. According to the customer, previous assembly times were decreased by 4 seconds.

Some issues facing the Manufacturer were manual placement of screws in the assembly process by the operators. Mishandled screws would lead to lost fasteners on the production floor or into the appliance product

For 2013, Design Tool Inc. is predicting an 8 to 10 percentage increase in Factory Automation spending in the manufacturer sector.

Screw sizes used in toys are becoming smaller today, as joint analysis and cost drive the manufacturer toward using the smallest fastener that will achieve the desired joint integrity.

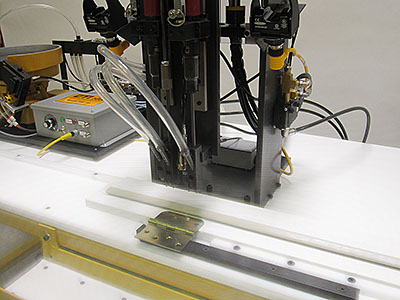

For decades, DTI has provided leading door manufacturers around the world with our patented multi-feed automatic screwdriver hinge machines to attach door hinges to their doorframes.

A major automotive manufacturer contacted Design Tool, Inc. to improve productivity and accuracy in counting and supplying four different types of fasteners simultaneously for an assembly kit supplied with various vehicles.

A leading Canadian-based steel products manufacturer approached DTI in need of a solution to preassemble their wide range of steel brackets with nuts and bolts for shipment with their products.