Plastics

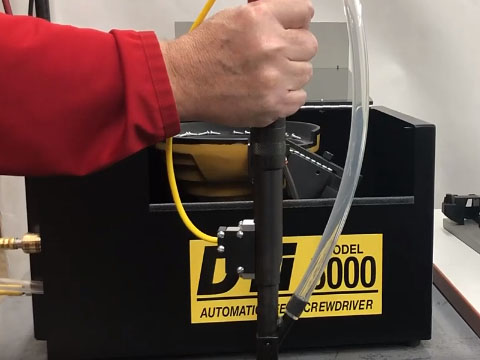

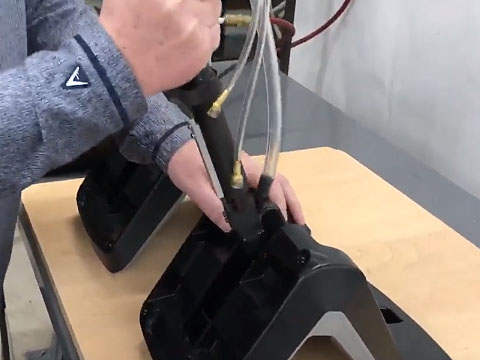

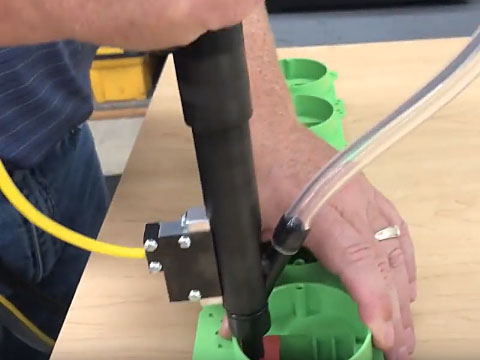

- DTI-5000 handheld systems can be designed for almost any fastening application, including counter-bored hole locations.

- DTI-5000 hand-held systems can be designed and built on almost any type or brand of screwdriver, providing greater flexibility for speed and power requirements.

- DC driver based systems allow complete control over the entire fastener driving process, insuring joint integrity to avoid problems with stripping fasteners.

- Drive-to-depth features on both handheld systems and fixtured components prevent product damage by driving the fastener to a specific depth.

- Systems can be designed for almost any screw type or drive.

With plastic playing such a large and vital role in today's manufacturing industry, DTI has extensive experience designing automation systems around a plethora of plastic applications. From trash cans to toys, consumer products, building supplies, gas pumps, outdoor equipment and many more, DTI is sure to provide you with the best solution available for your plastic needs. Design Tool Inc. offers handheld inline and pistol grip driver systems built on both pneumatic and DC electric screwdrivers. Driver RPM can be tailored to the application, avoiding problems with excessive speed and heat affecting joint integrity. Design Tool Inc. also offers fixtured components for assembly line integration, as well as turn-key assembly machines to meet almost fastening application. Each system is custom-designed for the individual application, insuring reliability, operator satisfaction, and increased productivity. Both handheld and fixtured systems can be equipped with drive-to-depth features that prevent product damage from overtightened fasteners. Turn-key systems can also offer poke-a-yoke features to prevent defective products from continuing the assembly process. Whether it's handhelds for your operators or fully-automated turn-key sub-assembly stations, DTI is sure to exceed your expectations.