Multiple Spindle Screwdriving Components

Design Tool Inc. offers multiple spindle screwdriving systems that machine builders or manufacturers can integrate into their assembly equipment. These multiple spindle systems are normally mounted on platen assemblies, and are fed by our single exit or dual exit feeding systems combined with our multi-feeding systems to allow the screwdriver assemblies to be fed from one bowl feeder. This feature maximizes value and minimizes space requirements for the bowl feeding system. Often, an auxiliary feed hopper is used to further increase screw capacity for longer run times between refilling.

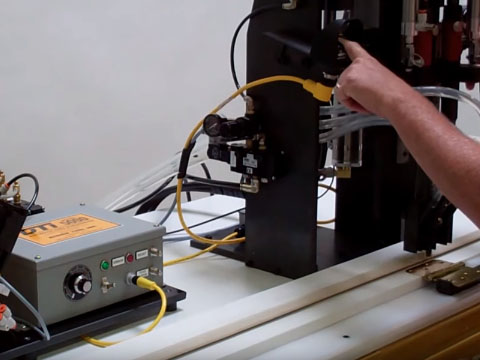

The platen assemblies can be designed with single or multiple spindles on each platen for design flexibility to meet almost any bolt spacing requirements. We offer pneumatic and DC electric screwdrivers and can build custom multiple spindle systems on most manufacturers’ screwdrivers. For example, we have built platen assemblies on Atlas-Copco, ASG, Desoutter, Ingersoll-Rand, Kolver, Stanley, and many other manufacturers including DC drivers.

ÂDesign Tool Inc. uses high quality linear bearing assemblies on all of our platen assemblies. We also use magnetic piston cylinders to provide positioning signals using solid state hall effect switches mounted on the cylinders for control logic capability. Platens can be constructed from aircraft grade aluminum alloy or steel, depending upon the customer’s requirements. We also offer high quality thrusters to position the multiple spindle systems if needed.

Design Tool Inc. patented single and dual exit feed mechanisms with our multi-feed systems insure that the multiple spindle screwdrivers are fed in the shortest cycle time possible. Screws can be staged in the feed tubes, and blown to the platen assemblies when the cycle starts. The feed systems can then reload the feed tubes while the screws are being driven, minimizing cycle time and increasing productivity. These feed systems allow greater flexibility in the design of the multiple spindle systems, giving Design Tool Inc. an advantage over our competitors in providing fast, reliable, and robust systems.