Automatic Screw Feeding and Screwdriving Fixtured Systems

Fully Automatic or Semi-automatic fastener feeding and driving systems from Design Tool, Inc. provide:

- The fastest assembly times

- Build on any screwdriver

- Multiple spindle screwdriving

- Fully automatic screwdriving with quality control and inspection

- Single station, standalone systems

- Fully integrated assembly line stations

- DC Electric, torque and angle control and monitoring screwdriving

- Multi-station parts placement and fastening

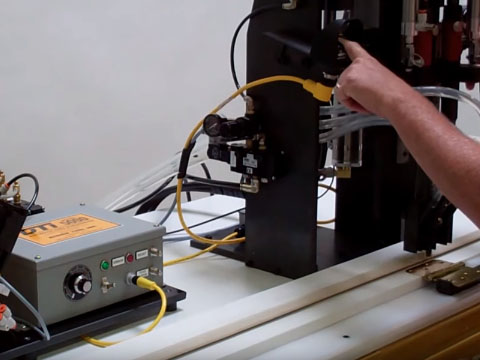

Design Tool Inc. offers turnkey fixtured systems to assemble components as a standalone station or fully integrated into the assembly line process.  The DTI fixtured screwdriving systems can be designed with single or multiple screwdriver spindles in fixed locations to accommodate a variety of fastener patterns.  Using proven and robust vertical thrusters, these machines offer higher volume productivity while reducing assembly cost.  Linear movement using linear bearings and cylinders or actuators is also available when required to meet a particular fastener pattern. The DTI 5000 multi-feed patented bowl feeder systems can deliver the fasteners to multiple drivers from a single bowl decreasing cycle time and improve productivity.

All machine movements are controlled by a PLC including feed actuation, vertical thruster movement, and driver advance to precisely control the location and fastener installation.  The pneumatic and electronic components used in the machine control logic has proven superior over many years of use.  Magnetic cylinder pistons and Hall Effect switches provide additional control parameters for machine operation.

These Fixtured screwdriver machines can be equipped with either pneumatic or DC electric screwdrivers for increased versatility.  If the machine uses multiple pneumatic drivers, it can be equipped with an air tank to provide sufficient volume for the pneumatic drivers to insure a stable air supply.  The DTI 5000 multi-feed patented bowl feeder systems can deliver the fasteners to multiple drivers from a single bowl decreasing cycle time and improve productivity.  These machines can also be designed with shuttle tables or indexers to allow the operator to load assemblies while the machine is in cycle, increasing operator efficiency and throughput. Custom part nests are designed to hold the components securely during the assembly process.

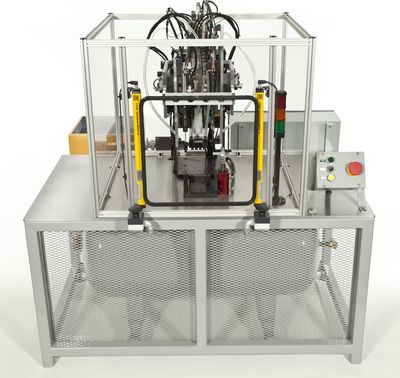

These Screwdriver assembly machines can be designed with a variety of safety systems to prevent operator injuries.¬† The machines can use light curtains and palm or opti-touch buttons to insure that the operator’s hands are clear of the assembly or loading area when the cycle begins.¬† Guards are also designed for each machine to eliminate the chance of someone entering the machine envelope during cycle.

The DTI turnkey fixtured systems are designed to each individual application and fastener. Each DTI machine is custom built and unique in design to exceed customer’s expectations.

Please contact us to discuss ideas on how to increase productivity with Automation.